Introduction

Maintaining your nugget ice maker is crucial for ensuring its optimal performance and longevity. Just like any other kitchen appliance, regular maintenance of your nugget ice maker helps in preventing potential issues and enhances its efficiency. Proper maintenance not only ensures the production of high-quality ice but also extends the lifespan of your machine, saving you from costly repairs or replacements in the long run.

Why Maintenance is Essential for Your Nugget Ice Maker

Regular maintenance of your nugget ice maker offers several benefits that contribute to both the machine’s performance and the quality of the ice produced:

- Consistent Ice Quality: Regular cleaning and maintenance help in producing consistently clear and pure ice. Over time, mineral deposits and impurities can accumulate in the machine, affecting the taste and clarity of the ice. By keeping your ice maker clean, you ensure that every batch of ice meets the highest standards of quality.

- Enhanced Efficiency: A well-maintained ice maker operates more efficiently, reducing energy consumption and operating costs. Regular maintenance tasks, such as descaling and cleaning the water lines, ensure that the machine runs smoothly without unnecessary strain on its components.

- Extended Lifespan: Just like any other appliance, the lifespan of a nugget ice maker can be significantly extended with proper care. Regular maintenance prevents the buildup of harmful deposits and wear and tear on critical parts, ensuring that your machine remains in top condition for years to come.

- Prevention of Breakdowns: Routine maintenance helps in identifying and addressing potential issues before they lead to major breakdowns. Regular inspections and cleaning can catch small problems early, preventing them from escalating into costly repairs.

- Optimal Performance: Maintaining your ice maker ensures that it operates at its best capacity, providing you with a steady supply of nugget ice whenever you need it. This is especially important for those who rely on their ice maker for hosting events or running a business.

Key Maintenance Practices

Here are some essential maintenance practices to keep your nugget ice maker in optimal condition:

- Daily Cleaning: After each use, wipe down the exterior of the ice maker and empty the ice bin. This prevents the accumulation of grime and keeps the machine looking clean and new.

- Weekly Cleaning: Once a week, perform a more thorough cleaning by removing and washing all removable parts. Use a mild detergent and warm water to clean these parts, then rinse and dry them thoroughly before reassembling.

- Descaling: Descale the machine every few months to prevent mineral buildup. Use a descaling solution recommended by the manufacturer and follow the instructions carefully. Descaling ensures that the internal components of the ice maker remain free of harmful deposits.

- Water Line Maintenance: Regularly inspect the water line for any signs of leaks or blockages. Clean the water line as needed to ensure a consistent flow of water into the ice maker. This is crucial for maintaining the quality of the ice and the efficiency of the machine.

- Filter Replacement: If your ice maker has a water filter, replace it according to the manufacturer’s recommendations. A clean filter ensures that the water used to make the ice is free of impurities, resulting in better-tasting ice.

Troubleshooting Common Issues

Despite regular maintenance, you may occasionally encounter issues with your nugget ice maker. Here are some common problems and their solutions:

- Low Ice Production: If your ice maker is producing less ice than usual, check for blockages in the water line or a dirty filter. Cleaning or replacing these components can often resolve the issue.

- Ice Quality Issues: If the ice is cloudy or has an off taste, it may be time to descale the machine and replace the water filter. Regular cleaning also helps in maintaining the clarity and taste of the ice.

- Water Line Leaks: Inspect the water line for any leaks or blockages. Tighten any loose connections and replace damaged sections of the line to prevent water leakage and ensure a consistent flow of water.

By following these maintenance practices and troubleshooting tips, you can keep your nugget ice maker running smoothly and enjoy high-quality ice for all your beverage needs. Regular care and attention to your ice maker not only enhance its performance but also ensure that it remains a reliable part of your kitchen for years to come.

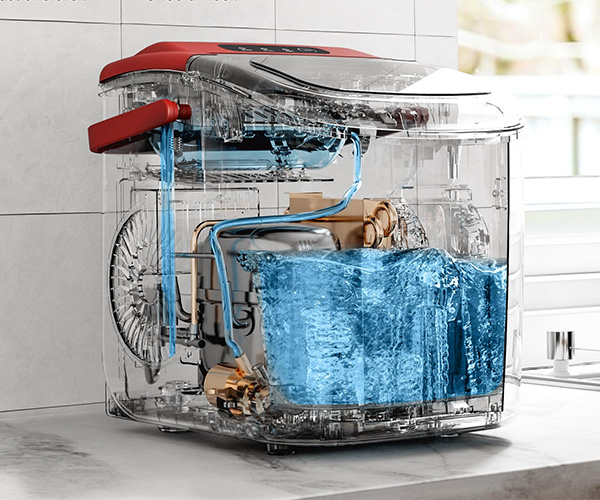

Key Components of a Nugget Ice Maker, Including the Water Line

Understanding the key components of a nugget ice maker is essential for proper maintenance and troubleshooting. Each part plays a critical role in the overall functionality and efficiency of the machine. Here’s a detailed look at these components:

1. Water Line

The water line is a crucial component of any nugget ice maker. It supplies the necessary water to the machine to produce ice. Proper maintenance of the water line ensures a consistent flow of clean water, which is essential for producing high-quality ice.

- Function: Provides a steady supply of water to the ice maker.

- Maintenance Tips: Regularly inspect for leaks or blockages. Clean the water line periodically to prevent buildup of minerals and impurities.

2. Refrigeration System

The refrigeration system is responsible for cooling the water and forming the ice. It includes several sub-components:

- Compressor: Pumps refrigerant through the system.

- Condenser: Releases heat absorbed from the water, cooling it down.

- Evaporator: The component where water is cooled and frozen into ice.

Maintaining these parts ensures efficient ice production and longevity of the machine.

3. Ice-Making Assembly

This is the heart of the nugget ice maker, where water is turned into nugget ice. The assembly includes:

- Ice Mold: Where water freezes to form ice nuggets.

- Auger: Moves the formed ice from the mold to the storage bin.

- Motor: Powers the auger to transport ice.

Regular cleaning of the ice-making assembly prevents mold and mineral buildup, ensuring the production of clean, high-quality ice.

4. Storage Bin

The storage bin holds the produced ice until it’s ready to be used. It is usually insulated to keep the ice from melting quickly.

- Capacity: Varies depending on the model, typically ranges from 1 to 5 pounds.

- Hygiene: Regularly clean the storage bin to prevent contamination and odor.

Proper maintenance of the storage bin ensures that the ice remains fresh and clean.

5. Control Panel

The control panel is the interface through which users operate the nugget ice maker. It allows for adjusting settings, starting and stopping the ice-making process, and monitoring the machine’s status.

- User Interface: Buttons or touchscreens for controlling the machine.

- Indicators: Lights or displays showing the status of the machine, such as power, ice production, and maintenance alerts.

Familiarizing yourself with the control panel can help you operate the machine more effectively and troubleshoot issues.

6. Filtration System

Many nugget ice makers come with a built-in filtration system to ensure that only clean, filtered water is used for ice production.

- Water Filter: Removes impurities from the water before it enters the ice-making process.

- Replacement Schedule: Follow the manufacturer’s recommendations for replacing filters, typically every 6 months.

Maintaining the filtration system is crucial for producing pure, high-quality ice.

Importance of Regular Maintenance

Regular maintenance of all these components is vital for the smooth operation and longevity of your nugget ice maker. Here are some best practices:

- Daily Cleaning: Wipe down surfaces and clean the ice bin.

- Weekly Cleaning: Clean the water line and check for any signs of wear or damage.

- Monthly Maintenance: Perform a thorough cleaning of the ice-making assembly and descale the machine if necessary.

- Annual Servicing: Have a professional inspect and service your ice maker to address any potential issues and ensure optimal performance.

By understanding and maintaining these key components, you can ensure that your nugget ice maker operates efficiently, produces high-quality ice, and lasts for years to come. Regular maintenance not only extends the life of your machine but also ensures that every beverage you enjoy is complemented by the perfect nugget ice.

Key Maintenance Practices: Detailed Steps for Descaling to Prevent Mineral Buildup

Descaling your nugget ice maker is a crucial maintenance step that helps prevent mineral buildup, ensuring efficient operation and longevity. Over time, minerals from water can accumulate inside the machine, affecting its performance and the quality of the ice produced. Here are the detailed steps for descaling your nugget ice maker:

Materials Needed

- Descaling solution (commercially available or a homemade mix of vinegar and water)

- Clean cloth or sponge

- Soft brush

- Container to catch runoff

- Gloves (optional for handling chemicals)

Step-by-Step Descaling Process

- Turn Off and Unplug the Ice Maker

- Ensure the nugget ice maker is turned off and unplugged to avoid any electrical hazards during the cleaning process.

- Empty the Ice Bin

- Remove any ice remaining in the ice bin and discard it. This will ensure the descaling solution does not contaminate the ice.

- Prepare the Descaling Solution

- Follow the instructions on the commercial descaling solution or mix a solution of equal parts white vinegar and water. Ensure you have enough solution to fill the water reservoir.

- Fill the Water Reservoir

- Pour the descaling solution into the water reservoir of the nugget ice maker. Ensure the reservoir is filled to the recommended level.

- Run the Cleaning Cycle

- If your ice maker has a cleaning cycle, activate it. This will circulate the descaling solution through the machine, dissolving mineral deposits. If there is no cleaning cycle, let the machine sit for 15-20 minutes to allow the solution to work.

- Brush and Wipe Internal Components

- While the solution is working, use a soft brush to gently scrub any visible mineral deposits inside the machine. Pay special attention to areas around the water line and ice-making components.

- Rinse Thoroughly

- After the cleaning cycle or soaking period, drain the descaling solution from the reservoir. Refill the reservoir with clean water and run a rinse cycle to remove any remaining solution. Repeat the rinse process if necessary to ensure all traces of the descaling solution are removed.

- Clean the Exterior

- Wipe down the exterior of the nugget ice maker with a clean cloth dampened with mild soap and water. This keeps the machine looking clean and presentable.

- Inspect and Reassemble

- Check all components for cleanliness and reassemble any parts that were removed. Ensure everything is securely in place before plugging the machine back in.

- Run a Batch of Ice

- Run a batch of ice and discard it to ensure no descaling solution remains in the system. This final step guarantees that your next batch of ice is clean and safe for consumption.

Additional Tips for Preventing Mineral Buildup

- Use Filtered Water: Using filtered water reduces the amount of minerals entering the ice maker, prolonging the time between descaling sessions.

- Regular Maintenance: Perform descaling at least once every three to six months, or more frequently if you notice a reduction in ice quality or production speed.

- Monitor Ice Quality: Keep an eye on the clarity and taste of your ice. Any changes may indicate it’s time to descale.

By following these detailed steps for descaling, you can keep your nugget ice maker running smoothly and efficiently, ensuring that it continues to produce high-quality ice. Regular maintenance not only extends the life of your appliance but also enhances your overall beverage experience.

Regular Inspection for Leaks or Blockages

Regular inspection for leaks or blockages is crucial for maintaining your nugget ice maker and ensuring it operates efficiently. Here’s a detailed guide on how to conduct these inspections and why they are important.

Importance of Regular Inspections

Performing regular inspections helps in early detection of issues that could affect the performance of your nugget ice maker. Leaks and blockages can lead to reduced ice production, compromised ice quality, and potential damage to the machine. By addressing these issues promptly, you can extend the lifespan of your appliance and maintain its optimal functionality.

Steps for Inspecting Leaks

- Visual Inspection: Start by visually inspecting the exterior and interior of the nugget ice maker. Look for any signs of water pooling or dripping around the machine.

- Check Connections: Examine all the water line connections. Ensure that hoses and connections are tightly secured and free from cracks or wear.

- Inspect the Water Line: Follow the water line from its source to the ice maker, checking for any signs of leaks or moisture. Pay special attention to joints and connectors, which are common sites for leaks.

- Test for Leaks: If you suspect a leak, turn off the water supply and carefully remove the water line. Check for moisture inside the line or around the connection points. Reconnect and tighten any loose fittings, and turn the water supply back on to see if the leak persists.

Steps for Inspecting Blockages

- Check Water Flow: Turn on the nugget ice maker and observe the water flow into the machine. Ensure that the water is flowing smoothly without interruptions.

- Examine the Water Filter: If your machine has a water filter, inspect it for any clogs or buildup that could restrict water flow. Replace the filter if it appears dirty or clogged.

- Clean the Water Line: Periodically clean the water line to prevent buildup of minerals or debris that can cause blockages. Use a mixture of water and vinegar or a commercial descaling solution to flush the line.

- Inspect the Ice Production Area: Check the area where ice is produced and stored for any obstructions. Remove any ice buildup or debris that could impede the ice-making process.

Benefits of Regular Inspections

- Preventative Maintenance: Regular inspections help identify and fix minor issues before they become major problems, saving time and money on repairs.

- Consistent Ice Quality: Ensuring there are no leaks or blockages maintains the quality and quantity of ice produced, providing you with a steady supply of nugget ice.

- Extended Appliance Lifespan: Regular maintenance and inspections can significantly extend the lifespan of your nugget ice maker, ensuring it remains a valuable part of your kitchen for years to come.

Tips for Effective Inspections

- Schedule Inspections: Set a regular schedule for performing inspections, such as once a month, to keep track of maintenance tasks.

- Keep Spare Parts Handy: Having spare parts like water filters and connectors on hand can help quickly address any issues discovered during inspections.

- Document Issues: Keep a log of any problems found and actions taken during inspections. This record can be helpful if you need to contact customer support or a professional repair service.

By following these steps and incorporating regular inspections into your maintenance routine, you can ensure that your nugget ice maker remains in top condition, providing you with high-quality, chewable ice whenever you need it. Regular maintenance not only enhances the performance of your appliance but also contributes to its longevity, making it a worthwhile investment for any home or business.

Ideal conditions for the ice maker

To ensure your nugget ice maker operates efficiently and produces high-quality ice, it’s crucial to maintain ideal conditions. These conditions will help the machine work at its best, providing you with the perfect nugget ice for your beverages. Here are some key aspects to consider:

Ambient Temperature

- Optimal Range: The ambient temperature around your nugget ice maker should ideally be between 50°F and 90°F (10°C to 32°C). Temperatures outside this range can affect the ice production rate and the quality of the ice.

- Avoid Extremes: Placing the ice maker in an environment that is too hot or too cold can cause the machine to overwork or underperform. For example, in a very hot room, the machine may struggle to maintain the necessary internal temperatures, while in a cold room, the water inside the machine could freeze prematurely.

Ventilation

- Adequate Airflow: Ensure there is sufficient space around the nugget ice maker for proper ventilation. Most ice makers have vents on the sides or back that need to remain unobstructed to allow for adequate airflow.

- Positioning: Place the ice maker at least a few inches away from walls and other appliances. This spacing helps prevent overheating and ensures that the machine can expel hot air effectively.

Humidity Control

- Low Humidity: High humidity levels can affect ice production and lead to condensation issues inside the machine. Ideally, the humidity should be kept below 60% to ensure the ice maker operates efficiently.

- Dehumidifiers: If you live in a particularly humid area, using a dehumidifier in the room with your ice maker can help maintain optimal humidity levels and improve the machine’s performance.

Electrical Supply

- Stable Power Source: Ensure your nugget ice maker is plugged into a stable power source. Fluctuations in power supply can lead to malfunctions or reduce the lifespan of the appliance.

- Dedicated Circuit: It is recommended to use a dedicated electrical circuit for your ice maker to prevent overloading and ensure consistent power delivery.

Water Supply

- Filtered Water: Using filtered water in your nugget ice maker can significantly improve the quality of the ice and reduce mineral buildup inside the machine. Filtered water is free from impurities that can affect the taste and clarity of the ice.

- Water Pressure: Maintain the appropriate water pressure as specified by the manufacturer. Insufficient water pressure can lead to poor ice production, while excessive pressure might damage the water line or internal components.

Regular Maintenance Checks

- Routine Inspections: Regularly inspect the nugget ice maker for any signs of wear and tear. Check the water line connections, clean the filters, and ensure the machine is operating smoothly.

- Cleaning Schedule: Follow a consistent cleaning schedule to prevent mold and bacteria buildup. This includes cleaning the water reservoir, ice bin, and any other parts that come into contact with water.

Placement and Environment

- Indoor Use: Although some models are designed for outdoor use, most nugget ice makers are best kept indoors where the environment is controlled.

- Stable Surface: Place the ice maker on a stable, level surface to avoid vibrations and ensure the machine operates without any physical strain.

Conclusion

By maintaining these ideal conditions, you can ensure that your nugget ice maker operates efficiently and produces high-quality ice consistently. Proper placement, stable environmental conditions, and regular maintenance are key to getting the best performance from your machine. Following these guidelines will not only enhance your ice-making experience but also extend the lifespan of your nugget ice maker, providing you with delicious, chewable ice for years to come.

Routine Checks: Key Components

Regularly inspecting key components like the condenser and evaporator in your nugget ice maker is crucial for maintaining optimal performance and extending the lifespan of your appliance. These components play a vital role in the ice-making process, and any issues with them can significantly impact the efficiency and quality of the ice produced.

Condenser Maintenance

The condenser is responsible for releasing the heat absorbed from the water during the ice-making process. To ensure your nugget ice maker operates efficiently, the condenser coils should be kept clean and free of dust and debris.

- Cleaning Frequency: It’s recommended to clean the condenser coils at least once every three months. In environments with higher dust levels, more frequent cleaning may be necessary.

- Cleaning Process: Use a soft brush or a vacuum with a brush attachment to gently remove dust and debris from the coils. For stubborn dirt, a damp cloth can be used, but ensure the coils are completely dry before powering the machine back on.

- Inspection: Regularly inspect the condenser for any signs of wear or damage. If you notice any bent fins or corrosion, it may be time to call a professional for further assessment.

Evaporator Maintenance

The evaporator in your nugget ice maker is where the water freezes and forms ice. Keeping the evaporator clean and well-maintained is essential for producing high-quality ice and maintaining efficient operation.

- Cleaning Frequency: The evaporator should be cleaned at least every six months, or more frequently if you notice a decrease in ice quality or production.

- Cleaning Process: Follow the manufacturer’s instructions for cleaning the evaporator. Typically, this involves using a cleaning solution specifically designed for ice machines. Run the cleaning cycle as directed, ensuring that all residual cleaner is thoroughly rinsed away to prevent contamination of the ice.

- Inspection: During cleaning, inspect the evaporator for any signs of scale buildup or corrosion. Descaling may be necessary if there is significant mineral buildup, which can hinder ice production and affect the taste and clarity of the ice.

Additional Routine Checks

In addition to maintaining the condenser and evaporator, several other routine checks can help keep your nugget ice maker running smoothly.

- Water Line: Ensure the water line is free of kinks, leaks, and blockages. Regularly replace water filters to maintain ice quality and prevent mineral buildup.

- Ice Bin: Clean the ice bin regularly to prevent mold and bacteria growth. Empty the bin and wipe it down with a mild disinfectant, ensuring it is thoroughly rinsed and dried before refilling.

- Thermostat Settings: Verify that the thermostat settings are correct and that the ice maker is operating within the recommended temperature range. Adjust as needed to optimize ice production and quality.

- Electrical Connections: Check all electrical connections for any signs of wear or damage. Ensure that the machine is properly grounded and that there are no loose wires or connections.

- Overall Inspection: Perform a general inspection of the entire machine, looking for any signs of wear, damage, or unusual operation. Address any issues promptly to prevent further damage and ensure the longevity of your appliance.

Conclusion

Regular maintenance and routine checks of key components like the condenser and evaporator are essential for keeping your nugget ice maker in top working condition. By following these best practices, you can ensure that your appliance operates efficiently, produces high-quality ice, and has a long service life. Investing time in regular maintenance not only enhances your beverage experience but also protects your investment in your nugget ice maker.

Troubleshooting Common Issues: Potential Reasons for Low Ice Output

When your nugget ice maker isn’t producing enough ice, it can be frustrating and impact your beverage experience. Understanding the potential reasons behind low ice output can help you troubleshoot and resolve the issue effectively. Here are some common causes and solutions:

1. Inadequate Water Supply

- Low Water Pressure: If the water pressure is too low, your ice maker may not receive enough water to produce ice efficiently.

- Solution: Check your home’s water pressure and ensure it meets the manufacturer’s recommended level. Installing a water pressure regulator might be necessary.

- Water Line Issues: Kinks or blockages in the water line can restrict water flow.

- Solution: Inspect the water line for any visible issues and straighten out any kinks. Clean or replace the water line if it’s blocked.

2. Dirty Water Filter

- Clogged Filter: A dirty or clogged water filter can impede water flow, reducing the ice maker’s ability to produce ice.

- Solution: Replace the water filter according to the manufacturer’s guidelines. Regular filter changes ensure optimal water flow and ice quality.

3. Temperature Problems

- Ambient Temperature: If the surrounding temperature is too high, it can affect the ice maker’s performance.

- Solution: Ensure the ice maker is placed in a well-ventilated area away from heat sources like stoves and direct sunlight. Maintaining a cooler ambient temperature helps improve efficiency.

- Internal Temperature: The internal temperature of the ice maker needs to be properly regulated for optimal ice production.

- Solution: Check the internal temperature settings and adjust them as needed. Make sure the condenser coils are clean and not obstructed.

4. Electrical Issues

- Power Supply Problems: Inconsistent or inadequate power supply can hinder the ice maker’s operation.

- Solution: Verify that the ice maker is properly plugged in and receiving adequate power. Check the outlet and circuit breaker to ensure they are functioning correctly.

- Faulty Components: Electrical issues within the ice maker, such as a malfunctioning motor or control board, can reduce ice output.

- Solution: Consult the user manual for troubleshooting tips or contact a professional technician for repair if you suspect an internal electrical issue.

5. Improper Maintenance

- Scale Buildup: Mineral deposits from hard water can accumulate in the ice maker, affecting performance.

- Solution: Regularly descale your nugget ice maker to prevent mineral buildup. Use a descaling solution and follow the manufacturer’s instructions.

- Dirty Components: Dust and debris can accumulate on the condenser coils and other components, reducing efficiency.

- Solution: Clean the condenser coils and other accessible parts regularly to maintain optimal performance.

6. Software or Control Issues

- Incorrect Settings: The ice maker’s settings might be improperly configured, affecting ice production.

- Solution: Review the user manual to ensure the settings are correctly adjusted for your needs. Reset the ice maker to default settings if necessary.

- Firmware Updates: Outdated firmware can sometimes cause performance issues.

- Solution: Check if the manufacturer offers firmware updates for your model and follow their instructions to update the device.

7. Overuse or Heavy Demand

- High Demand: If you’re using more ice than the machine can produce, it may seem like the output is low.

- Solution: Assess your ice needs and consider using an additional ice maker if your demand consistently exceeds the production capacity of your current unit.

Conclusion

Low ice output from your nugget ice maker can often be traced back to a few common issues. By understanding and addressing these potential problems—whether it’s a water supply issue, temperature control, or maintenance—you can ensure your ice maker operates efficiently and keeps your beverages perfectly chilled.

Indicators that Professional Maintenance is Needed

Maintaining a nugget ice maker is generally straightforward, but there are times when professional maintenance is essential to ensure your machine operates at peak performance. Knowing when to call in a professional can prevent minor issues from escalating into major problems, saving you time and money in the long run. Here are some key indicators that it’s time to seek professional help for your nugget ice maker:

Persistent Low Ice Production

- Consistent Reduction: If you notice a consistent decrease in ice production, despite regular maintenance and cleaning, it may indicate a deeper issue that requires professional diagnosis and repair.

- Unusual Ice Cycles: Irregular ice-making cycles or prolonged periods between ice batches can also be a sign that your machine needs professional attention.

Poor Ice Quality

- Discoloration: Ice that appears cloudy, discolored, or contains impurities suggests that there might be an internal issue affecting the water supply or filtration system.

- Off-Taste: If the ice has an unusual taste or odor even after cleaning the machine and replacing filters, it’s advisable to get a professional to inspect the water line and internal components.

Strange Noises

- Unusual Sounds: Any new or unusual noises coming from the nugget ice maker, such as grinding, clicking, or loud humming, can indicate mechanical problems. Professional technicians can accurately diagnose and fix these issues.

- Vibration: Excessive vibration or shaking of the machine could suggest that parts are misaligned or worn out, requiring professional adjustment or replacement.

Water Line Issues

- Leaks: Persistent leaks from the water line or within the machine itself are clear signs that professional intervention is needed to prevent water damage and ensure proper operation.

- Blockages: If blockages in the water line are frequent and difficult to clear, a professional can inspect and clean the system more thoroughly.

Electrical Problems

- Frequent Cycling: If your nugget ice maker is frequently turning on and off, it may indicate electrical issues that require professional troubleshooting and repair.

- Power Issues: Complete failure to power on or frequent power outages while the machine is running can signify underlying electrical problems that are best handled by a professional.

Software Malfunctions

- Smart Features Not Working: For nugget ice makers with smart technology, if features like Wi-Fi connectivity or app control stop working correctly, it may necessitate a professional firmware update or software repair.

- Control Panel Issues: Malfunctioning control panels or unresponsive buttons can be complex to fix and are best handled by a qualified technician.

Frequent Maintenance Needs

- Repeated Problems: If you find yourself repeatedly dealing with the same issues despite following all maintenance guidelines, it’s a sign that a professional assessment is necessary to identify and fix the root cause.

- High Maintenance Costs: When the cost of frequent minor repairs starts adding up, it might be more cost-effective to have a professional perform a thorough inspection and overhaul of your nugget ice maker.

Benefits of Professional Maintenance

- Expert Diagnosis: Professionals can accurately diagnose issues that may not be apparent to the average user, ensuring that all potential problems are addressed.

- Comprehensive Service: Professional maintenance includes thorough cleaning, descaling, and inspection of all components, extending the life of your nugget ice maker.

- Warranty Protection: Utilizing professional services can help maintain the validity of your machine’s warranty, protecting you from high costs of major repairs.

Conclusion

Understanding the signs that indicate the need for professional maintenance can help you keep your nugget ice maker in top condition. Regular professional check-ups not only ensure the longevity of your machine but also enhance its performance, ensuring you always have the best quality nugget ice for your beverages.

Insights from Industry Professionals on Best Maintenance Practices

Maintaining your nugget ice maker effectively requires insights from those who know the machines best: industry professionals. These experts provide valuable tips and guidelines to ensure your ice maker operates at peak efficiency and longevity.

Regular Cleaning and Sanitization

- Daily and Weekly Cleaning: Experts recommend a daily wipe-down of the exterior and a weekly clean of the internal components. This prevents the buildup of grime and bacteria, ensuring your ice remains clean and safe to consume.

- Sanitization: Use a food-safe sanitizer to clean the ice bin and water reservoir regularly. Professionals stress the importance of following manufacturer guidelines to avoid any damage to the machine.

Descaling

- Frequency: Descale your nugget ice maker every six months, or more frequently if you notice a decrease in ice production or changes in ice quality. This prevents mineral buildup that can clog the system and reduce efficiency.

- Descaling Process: Use a descaling solution recommended by the manufacturer. Run a complete cycle with the solution, followed by multiple cycles with clean water to rinse thoroughly.

Water Quality

- Filtered Water: Use filtered water to reduce impurities and mineral deposits. Many professionals suggest installing a dedicated water filter system for your ice maker to ensure consistent water quality.

- Filter Replacement: Replace water filters every six months or as specified by the manufacturer. This maintains water purity and prevents clogs in the water line.

Temperature and Ventilation

- Ambient Temperature: Keep your nugget ice maker in a well-ventilated area with a stable temperature. Avoid placing it near heat sources or in direct sunlight.

- Ventilation: Ensure adequate space around the machine for proper airflow. Blocked vents can cause the machine to overheat and reduce its efficiency.

Routine Inspections

- Visual Checks: Regularly inspect the machine for any signs of wear and tear, leaks, or unusual noises. Addressing small issues early can prevent more significant problems down the line.

- Performance Monitoring: Keep an eye on the quality and quantity of ice produced. Any noticeable changes can indicate a need for maintenance or professional servicing.

Professional Servicing

- Scheduled Maintenance: Arrange for professional maintenance at least once a year. Technicians can perform in-depth cleaning, descaling, and inspections that go beyond routine user maintenance.

- Service Agreements: Consider signing a service agreement with a reputable provider. This ensures regular maintenance and can extend the life of your nugget ice maker.

Common Issues and Troubleshooting

- Ice Production: If the machine produces less ice than usual, check for clogs in the water line, clean the filters, and descale the machine.

- Ice Quality: If the ice is cloudy or tastes off, it might be due to dirty water lines or filters. Regular cleaning and filter replacement can resolve this.

- Machine Noises: Unusual noises often indicate mechanical issues. Turn off the machine and inspect for loose parts or blockages. If the problem persists, contact a professional.

Additional Tips

- Manual Reference: Always keep the user manual handy for specific maintenance guidelines and troubleshooting steps. Manufacturers provide detailed instructions tailored to your specific model.

- Spare Parts: Keep essential spare parts, such as filters and cleaning solutions, on hand. This ensures you can perform maintenance tasks promptly without waiting for supplies.

Conclusion

By following these best practices from industry professionals, you can ensure your nugget ice maker remains in excellent condition, providing you with high-quality ice for years to come. Regular maintenance not only extends the life of your machine but also enhances its performance, ensuring you always have the perfect nugget ice for your beverages.

Providing Actionable Tips to Common Maintenance Questions

Maintaining a nugget ice maker can seem daunting, but with the right knowledge and a few practical tips, you can ensure your machine runs smoothly and produces high-quality ice consistently. Here are some actionable tips to help you address common maintenance questions and keep your nugget ice maker in top condition.

How Often Should I Clean My Nugget Ice Maker?

- Daily Maintenance: Wipe down the exterior and clean the ice bin daily to prevent mold and bacteria buildup.

- Weekly Cleaning: Perform a more thorough cleaning weekly, including scrubbing the ice bin with a mild detergent and rinsing it well.

- Deep Cleaning: Every 1-3 months, conduct a deep cleaning. Use a manufacturer-recommended cleaning solution to descale and sanitize the internal components.

What Is the Best Way to Descale a Nugget Ice Maker?

- Descaling Solution: Use a commercial descaling solution designed for ice makers. Follow the manufacturer’s instructions for mixing and applying the solution.

- Descaling Frequency: Descale your nugget ice maker every 3-6 months, depending on your water hardness. Hard water can cause mineral buildup, which impairs ice production.

- Descaling Process: Run the descaling solution through the machine as if you were making ice, then thoroughly rinse the machine by running several cycles with clean water.

How Can I Prevent Ice from Tasting Bad?

- Use Filtered Water: Always use filtered water in your nugget ice maker. This reduces the presence of impurities and minerals that can affect the taste of the ice.

- Regular Cleaning: Clean the machine and replace water filters regularly to prevent bacterial growth and buildup of impurities.

- Check Water Supply: Ensure your water supply is clean and free from contaminants. Occasionally flush the water line to remove any buildup.

How Do I Deal with Low Ice Production?

- Check Water Supply: Ensure that the water line is not kinked or blocked and that there is adequate water pressure.

- Clean the Machine: A dirty machine can slow down ice production. Ensure all components are clean and free from buildup.

- Temperature Control: Ensure the ambient temperature around the machine is within the recommended range (typically 50-90°F). Too hot or too cold environments can affect ice production efficiency.

How Can I Fix a Leaky Water Line?

- Inspect Connections: Regularly check all connections for signs of wear or damage. Tighten any loose fittings.

- Replace Damaged Parts: If you find any cracks or leaks in the water line, replace the damaged section promptly to prevent further issues.

- Use Quality Parts: Ensure that all replacement parts are of high quality and compatible with your specific nugget ice maker model.

How Do I Maintain the Ice Quality?

- Regular Maintenance: Follow a strict maintenance schedule for cleaning and descaling.

- Proper Storage: Store the ice in a clean, odor-free environment. Avoid storing ice next to strong-smelling foods to prevent odor transfer.

- Monitor Ice Quality: Regularly check the ice for clarity and taste. Any changes can indicate a need for cleaning or maintenance.

What Should I Do If My Nugget Ice Maker Stops Working?

- Basic Troubleshooting: Check the power supply, ensure the machine is properly plugged in, and reset the machine according to the manufacturer’s instructions.

- Check for Blockages: Inspect the ice bin and water line for any blockages that could be causing the machine to stop.

- Professional Help: If basic troubleshooting doesn’t resolve the issue, contact a professional technician. Many nugget ice makers come with a warranty, so check if your machine is still covered for repairs.

How Do I Keep the Water Line Clean?

- Regular Flushing: Flush the water line monthly to prevent mineral and bacterial buildup. Use a mixture of water and vinegar or a commercial water line cleaner.

- Filter Replacement: Replace the water filter every 6 months or as recommended by the manufacturer to ensure clean water supply.

- Inspect for Leaks: Regularly inspect the water line for leaks or cracks, and replace any damaged sections promptly.

Conclusion

To ensure your nugget ice maker consistently delivers high-quality ice and operates efficiently, it’s crucial to adhere to the maintenance practices outlined in this guide. Regular maintenance not only extends the lifespan of your appliance but also enhances its performance, ensuring you always have the best ice for your beverages.

By incorporating these best practices into your routine, you can enjoy the full benefits of your nugget ice maker. Here’s a quick recap of what you should focus on:

- Regular Cleaning:

- Daily: Wipe down the exterior and clean the ice bin to prevent bacterial growth.

- Weekly: Perform a more thorough cleaning, including the water reservoir and any removable parts.

- Deep Cleaning: Follow the manufacturer’s guidelines for a deep clean, typically every few months, using recommended cleaning solutions.

- Descaling:

- Frequency: Depending on your water hardness, descale your ice maker every 3-6 months to prevent mineral buildup.

- Procedure: Use a descaling solution as recommended by the manufacturer. Ensure the solution circulates through the entire system, including the water line.

- Water Line Maintenance:

- Inspection: Regularly inspect the water line for any signs of leaks or blockages.

- Cleaning: Flush the water line periodically to maintain water quality and ensure efficient ice production.

- Use Filtered Water:

- Benefits: Using filtered water reduces impurities that can clog your ice maker and affect the taste and quality of the ice.

- Filter Replacement: Change the water filter according to the manufacturer’s recommendations, typically every 6 months.

- Temperature Control:

- Ambient Temperature: Keep your ice maker in an environment with stable temperatures to avoid overworking the appliance.

- Internal Temperature: Monitor and maintain the recommended internal temperature settings to optimize ice production.

- Routine Checks:

- Components Check: Inspect key components like the condenser and evaporator coils for cleanliness and functionality.

- Performance Monitoring: Regularly check the quality and quantity of ice produced to catch any issues early.

- Troubleshooting Common Issues:

- Low Ice Production: Check for blockages, proper water flow, and clean the machine thoroughly to resolve this issue.

- Ice Quality Issues: Ensure the water used is clean, and the machine is regularly cleaned and descaled.

- Water Line Problems: Address leaks and blockages immediately to prevent bigger issues.

By following these practices, you can ensure that your nugget ice maker remains in peak condition, providing you with the highest quality ice for all your beverages. Whether you’re enjoying a refreshing cold drink on a hot day or making cocktails for a gathering, a well-maintained nugget ice maker enhances your beverage experience.

For more detailed guides and professional insights on maintaining home appliances, visit homesolutionzone.com/blog. Here, you’ll find a wealth of information designed to help you get the most out of your home appliances and improve your overall living experience. Keep your nugget ice maker in top shape and enjoy the perfect ice every time.